Tooling & Mold Production

A mold that is perfected properly is the foundation of dependable production. Molding services focused on the production of engineering molds for prototyping, bridging, and even full production, are implemented with the three characteristics of precision, quality, and efficiency. We consider every detail from the very first steel cut to the final confirmation and apply art and engineering discipline to ensure your molds work just like you imagined.

A mold that is perfected properly is the foundation of dependable production. Molding services focused on the production of engineering molds for prototyping, bridging, and even full production, are implemented with the three characteristics of precision, quality, and efficiency. We consider every detail from the very first steel cut to the final confirmation and apply art and engineering discipline to ensure your molds work just like you imagined.

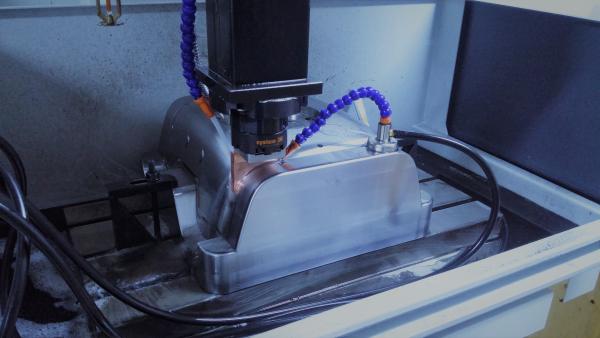

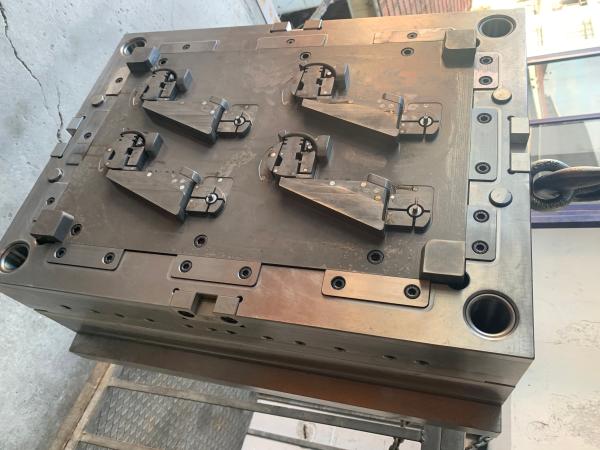

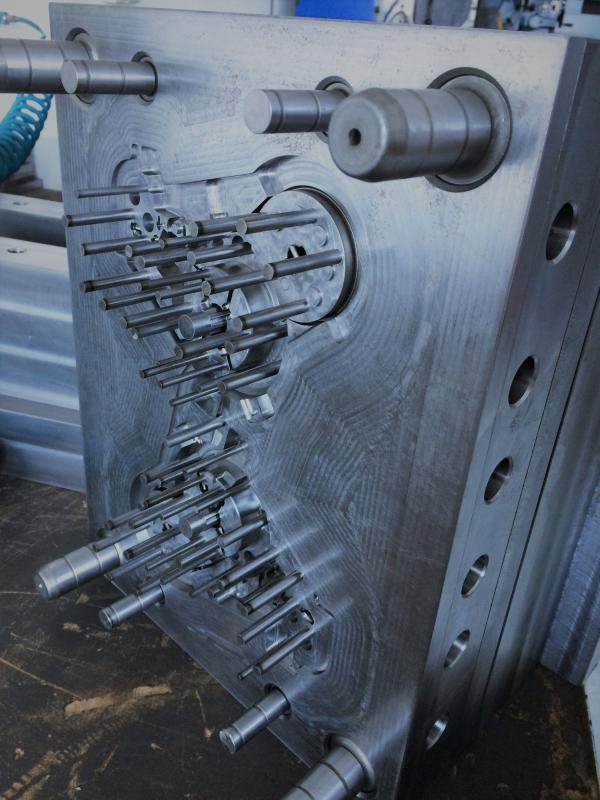

We start with choosing the materials and manufacturing processes that are the best fit for your product. For example, aluminum tooling may be the best choice for quick turnaround prototypes or for low-volume production, while hardened steel molds are built to last and can handle millions of cycles. Every tool is designed in detail—proper venting, cooling, ejection, and gating are all taken into account to improve part quality and cycle time.

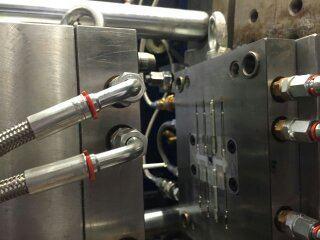

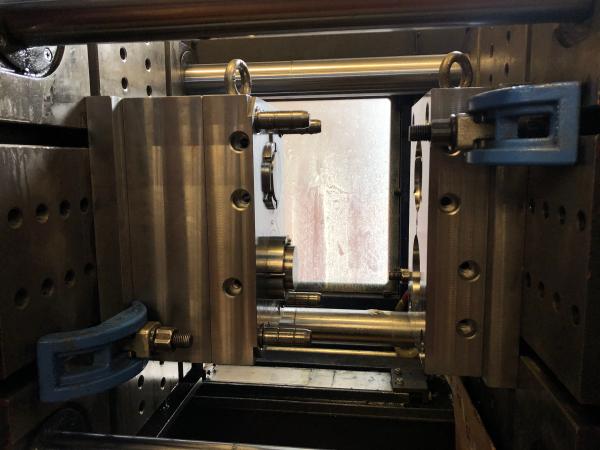

Among the services rendered in-house is high-precision CNC machining, EDM (electrical discharge machining), polishing, and assembly. Each part, including cores, cavities, slides, and lifters, is produced, and assembled within close tolerances. The guarantee of precision means that your parts will be identical from the first shot to the last one, which in turn results in no downtime and no reworks.

We know very well that speed is of utmost importance. To support this, we provide bridge tooling and quick mold programs as an option that allows you to test designs and get to market much faster. These options are capable of delivering production-quality parts immediately with no slow lead times that are common with traditional tooling, thereby allowing flexibility for pilot runs or early product introduction.

Once production is started, we will still be taking care of your tools through our routine maintenance programs and rapid-response repair. Our programmers can make mold modifications and engineering changes to incorporate design updates, cut down on flash, or enhance part performance. Our philosophy is that proper tooling should move along with your product, not hold it back.

It doesn't matter whether your mold has to be a plain cold runner or an intricate hot runner system, a single-cavity or a multi-cavity setup, our objective is still the same: to provide tools that make superb parts, cycle after cycle. With a combination of technology, expertise, and dependability, we make your production process uninterrupted and your investment fruitful for many years.